Call Us: +91 9653168791

Hastelloy C22 Pipes

- Home

- Hastelloy C22 Pipes

Hastelloy C22 Pipes Manufacturer and Supplier in India

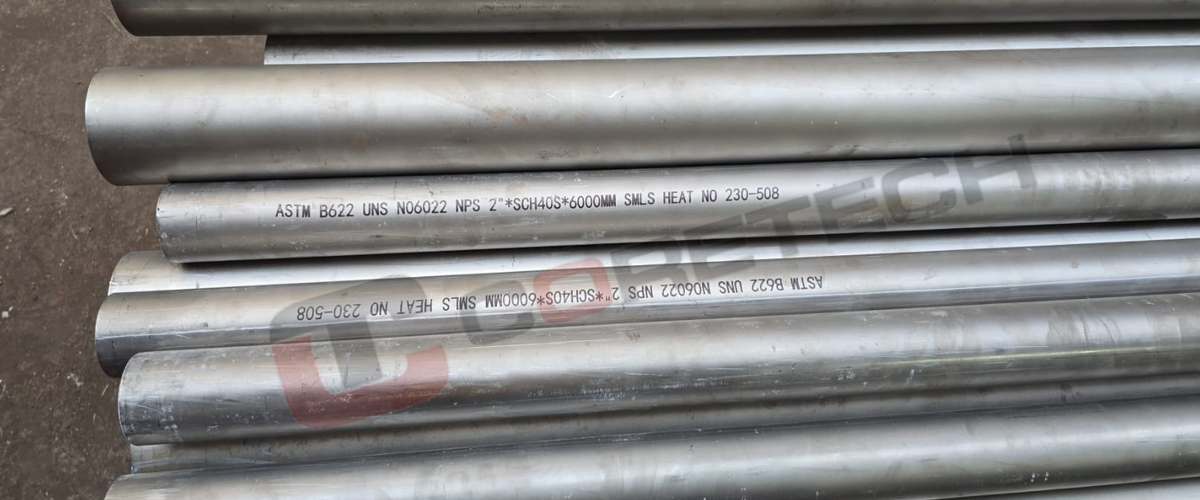

Hastelloy C22 Industrial Pipes, Hastelloy C22 Seamless Pipes Supplier, WERKSTOFF NR. 2.4602 Electropolish Pipe, Hastelloy C22 Welded Pipes Exporter

Hastelloy C22 pipes are noted for their high corrosion resistance, making them perfect for usage in demanding environments such as chemical processing, maritime, and aerospace sectors. These pipes have excellent resistance to pitting, crevice corrosion, and stress corrosion cracking, assuring long-term performance in harsh environments. Coretech Speciality Alloys manufactures and supplies high-quality Hastelloy C22 pipes that satisfy the most severe industry durability and reliability criteria. To accommodate a wide range of industrial applications, we provide pipes in a variety of sizes and specifications.

Coretech Speciality Alloys, a trusted Hastelloy C22 pipe manufacturer and supplier, is dedicated to providing high-quality products via precision engineering and experienced workmanship. Whether you want seamless or welded pipes, we provide tailored solutions to meet your individual project needs. Our staff promises prompt delivery and cheap cost without sacrificing quality. For queries and orders, please contact us at sales@coretechspecialityalloy.com. We will provide the finest Hastelloy C22 solutions for your industry.

ASTM B619 Alloy C22 SMLS Pipes, Best Price for Hastelloy C22 Pipe, ASME SB622 C22 Pipes Manufacturers in Mumbai, India.

Hastelloy C22 Pipes Specification

| Hastelloy C22 Pipes Standards | ASTM B622, B619 / ASME SB622, SB619 |

|---|---|

| Dimensional Specification | ANSI/ASME B36.19M, ANSI/ASME B36.10M |

| ASTM B622 C22 Seamless Pipe Size | Length: 0.5 to 12 meter, WT: 0.5 to 30mm, OD: 3 to 600mm | Custom Sizes |

| ASTM B622 C22 Welded Pipe Size | Length: 0.5 to 12 meter, WT: 0.35 to 6.mm, OD: 6 to 200mm | Custom Sizes | Alloy C22 Pipe Thick Wall Pipe Size | Length: 0.5 to 12 meter, WT: 2.5 to 100.mm, OD: 10 to 600mm | Custom Sizes |

| Hastelloy C22 Pipes Manufacturing Shapes | Round, Square, Rectangular |

| Nickel Alloy C22 Pipe Manufacturing Techniques | Seamless / Welded / ERW / Fabricated |

| Hastelloy Alloy C22 Pipe Schedule Thickness Range | SCH 5, SCH10, SCH 40, SCH 80, SCH 80S, SCH 160, SCH XXS, SCH XS |

| Hastelloy C22 Pipes End Types | Plain End, Beveled End |

| Hastelloy C22 Annealed Pipe Finish | Polished, Bright, Annealing, Mirror |

| Alloy C22 Clad Pipe Technique | Cold Formed, Precision Bend, Hot Formed |

| Hastelloy C22 Pipe Packaging | Bubble wraps, Woodem Boxes, Steel Strips Bundled, Custom |

Hastelloy C22 Pipe Equivalent Grades

| STANDARD | WERKSTOFF NR. | UNS | JIS | GOST | EN | OR |

| Hastelloy C22 | 2.4602 | N06022 | NW 6022 | ХН65МВУ | NiCr21Mo14W | ЭП760 |

Hastelloy C22 Pipe Chemical Composition

| Grade | C | Mn | Si | S | Co | Ni | Cr | Fe | Mo | P |

| C22 | 0.010 max | 1.00 max | 0.08 max | 0.03 max | 2.50 max | 50.99 min* | 14.50 – 16.50 | 4.00 – 7.00 | 15.00 – 17.00 | 0.04 max |

Hastelloy C22 Pipe Mechanical Properties

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Hastelloy C22 | 8.89 g/cm3 | 1370 °C (2500 °F) | Psi – 1,15,000 , MPa – 790 | Psi – 52,000 , MPa – 355 | 40 % |

Types of Hastelloy C22 Pipes

- Hastelloy C22 Seamless Pipe Manufacturer

- Alloy C22 Welded Pipes Supplier

- 2.4602 Welded Pipe Manufacturer

- UNS N06022 Seamless Pipe Stockist

- Hastelloy C22 ERW Pipes Exporter

- C22 Hastelloy EFW Pipe Dealer

- Hastelloy C22 Square Pipes Supplier

- UNS N06022 Rectangular Pipe Manufacturer

- ASTM B619 C22 Electropolish Pipe

- Nickel Alloy NW 6022 Polished Piping

- Hastelloy C22 Industrial Pipes Manufacturer

- Alloy C22 Fabricated Pipe Manufacturer

Hastelloy C22 Pipes – Industries & Applications

Global Destinations for Our Hastelloy C22 Pipe Exports

Major Domestic Cities We Supply Hastelloy C22 Pipes

Send us your requirement for

Hastelloy C22 Pipes

sales@coretechspecialityalloy.com

Hastelloy Products

- Hastelloy C22 Pipes

- Hastelloy C276 Pipes

- Hastelloy C22 Tubes

- Hastelloy C276 Tubes

- Hastelloy C22 Round Bars

- Hastelloy C276 Round Bars

- Hastelloy C22 Buttweld Fittings

- Hastelloy C276 Buttweld Fittings

- Hastelloy C22 Forged Fittings

- Hastelloy C276 Forged Fittings

- Hastelloy C22 Flanges

- Hastelloy C276 Flanges

- Hastelloy C22 Sheets & Plates

- Hastelloy C276 Sheets & Plates

- Hastelloy C22 Fasteners

- Hastelloy C276 Fasteners

Hastelloy Pipes

- Corrosion-Resistant Hastelloy C22 Pipes for Incineration Plants

- Hastelloy C22 Pipes for Acid Production Plants

- Hastelloy C22 Pipes for Aerospace Components

- Hastelloy C22 Pipes for Bioreactors & Clean Rooms

- Hastelloy C22 Pipes for Chemical Processing

- Hastelloy C22 Pipes for Marine Exhaust Systems

- Hastelloy C22 Pipes for Nitric Acid Applications

- Hastelloy C22 Pipes for Offshore Oil Rigs

- Hastelloy C22 Pipes for Pharmaceutical Production

- Hastelloy C22 Pipes for Sour Gas Environments

- Hastelloy C22 Pipes for Wastewater Treatment Plants

- Hastelloy C276 Pipes for Flue Gas Desulfurization Systems

- Hastelloy C276 Pipes for Heat Exchangers in Chemical Plants

- Hastelloy C276 Pipes for Nuclear Power Plants

- Hastelloy C276 Pipes for Seawater Applications

- Hastelloy C276 Pipes for Sulfuric Acid Handling

- High Strength Hastelloy C22 Pipes for Turbine Exhausts

- High-Temperature Hastelloy C276 Pipes for Refineries

- Saltwater-Resistant Hastelloy C276 Pipes

- Sanitary Grade Hastelloy C276 Pipes for Food Industry